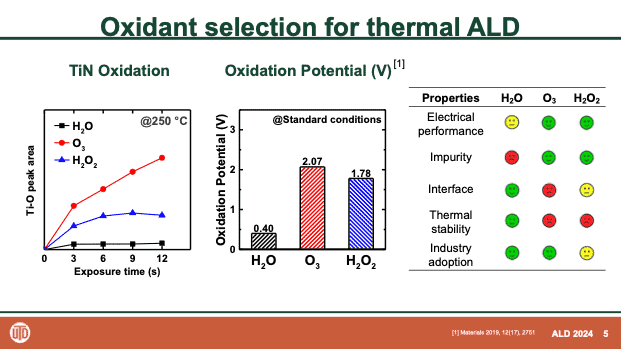

The effect of interface between the insulator and the metal becomes increasingly significant as the insulator thickness scales beyond sub-5nm in Metal-Insulator-Metal (MIM) capacitors in memory applications. The formation of series capacitors reduces total capacitance of each memory cell, and interfacial oxide may hinder crystallization of the insulator layer due to being interfacial energy dominant, which both directly affect the device performance and reliability. Co-reactants such as H2O and O3 are widely used in commercial processes to deposit an insulator layer; however, while H2O may minimize the formation of an interfacial oxide, it suffers from poor film quality from unreacted ligands that increase leakage current which drives the capacitance down. Conversely, O3, owing to its strong oxidation potential, can deposit high quality film, but at the cost of increased growth of an interfacial oxide layer. This work focused on exploring anhydrous H2O2 or H2O2/H2O mixtures as the new co-reactant that can achieve minimum interfacial oxide with the ability to deposit a high-quality insulator layer to enable further scaling of memory technologies.

In this work, HfO2 was deposited on 90nm sputtered TiN at 250°C using (NMe2)3Hf (TDMA-Hf) and anhydrous H2O2 or H2O2/H2O mixture. IR absorption spectra after each ALD half cycle was measured to analyze surface the surface reaction mechanism to assess the effect of mixing two oxidants. The study found that the oxidation of TiN can be controlled by modulating the H2O2/H2O ratio.