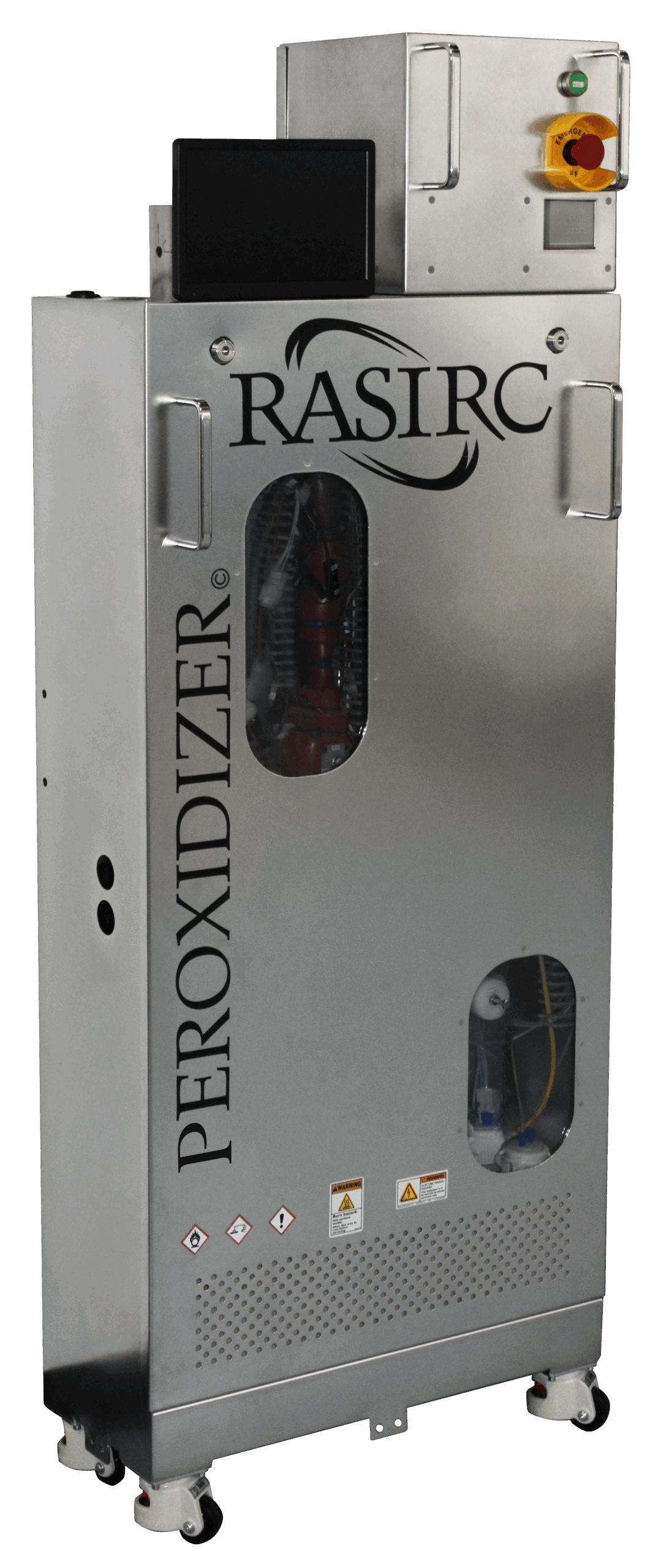

High Concentration Hydrogen Peroxide Gas Delivery System

The RASIRC Peroxidizer provides a safe, reliable way to deliver bulk, high-concentration hydrogen peroxide gas into ALD, annealing, dry surface preparation and cleaning processes.

- Safely concentrates H2O2 from semiconductor grade 30% weight H2O2

- Delivers H2O2 gas at concentrations up to 50,000ppm

- Compatible with carrier gas flowrates of 0 – 30slm

- Membrane based vaporizer enables high purity H2O2 gas delivery without entrained droplets or decomposition

Peroxidizer Beats Traditional Delivery Methods

High Concentration

The Peroxidizer delivers 10x concentration of hydrogen peroxide gas at a given temperature and delivers droplet-free gas at temperatures as low as 80°C. The Peroxidizer delivers up to 50,000ppm of hydrogen peroxide gas by volume from 30% hydrogen peroxide liquid solution.

Bigger Process Window, More Precursor Options

New materials and architectures are more temperature sensitive than their predecessors, forcing lower thermal budgets. Hydrogen peroxide gas from the Peroxidizer has higher reactivity at lower temperature, increasing the range of precursors available to process engineers.

Strong Oxidant without Interface Damage

Hydrogen peroxide gas readily converts to highly reactive OH radicals, creating a high-density ALD nucleation and faster reactions with precursors. Due to combustion reactions when using Ozone and Oxygen plasma, oxidation can penetrate below the interface layer, damaging the bottom electrode and surface structures. H2O2 reacts via ligand exchange, providing high reactivity with low interface growth.

Low Temperature

High concentration hydrogen peroxide gas delivered by the Peroxidizer creates a dense hydroxylated layer at a lower operating temperature than other oxidants. To achieve the same level of reactivity, water requires higher process temperatures that are not compatible with new materials.

Peroxidizer® Competitive Advantage for SAMP Spacer

The Internet of Things requires low power and high performance semiconductor devices, which will only be enabled through new materials and 3D architectures. These new devices must be processed at lower temperature and more care must be taken to avoid damaging complicated physical structures during cleaning processes. As processes scale, oxidants must also be able to support high volume ALD.

The Peroxidizer is the first tool to enable stable and particle-free delivery of high concentration hydrogen peroxide gas, enabling lower process temperatures, greater use of new materials and high process throughput.

Hydrogen Peroxide gas eliminates problems associated with other oxidants used in semiconductor fabrication processes. Ozone and oxygen plasma are too aggressive, penetrating below the interface layer and damaging both surface structures and bottom electrodes. Both ozone and water lead to dense interface layers.

In addition, plasma cannot deeply penetrate high aspect structures, resulting in non-uniform step coverage/conformality and non-uniform etch rates.

Water is less reactive than hydrogen peroxide gas and requires higher process temperatures. These properties make water a poor choice with new materials, new precursors, and lower thermal budgets.

Hydrogen peroxide gas is more reactive than water at low temperatures. High reactivity enables process engineers to use precursors that normally would not react with water or ozone. This reactivity also results in active removal of carbon.

Hydrogen peroxide gas achieves higher density nucleation than other oxidants. Hydrogen peroxide has less steric hindrance than water or ozone because it decomposes into hydroxyls on surfaces. The resulting dense layer of hydroxyls creates an ideal surface for ALD.