Key Challenges for Device Performance

Parasitic Losses

Device performance and size are limited by material heat tolerance in Middle of the Line (MOL) and Back-End of the Line (BEOL) processes. Improved metal contacts, thinner barrier layers and thinner liners are required to minimize parasitic losses as devices shrink.

New Channel Materials

Current processes for next generation channel materials in logic devices are inadequate. Integration imposes new low temperature constraints for several process steps including TiN electrode, AlN2 heat spreader, GaN, and SiN side wall deposition.

Vertical Scaling

Memory density requirements for future 3-D NAND devices requires large increases in vertical scaling. Temperature limits on SiN deposition will continue to decrease from 550°C.

Solving Device Performance Challenges

Low Temperature

Hydrazine gas creates low resistivity TiN, SiN, AlN2, GaN, and InGaN films by growing nitrides at lower temperatures than with ammonia.

Uniform High Aspect Ratio Deposition

Hydrazine gas deposits uniform nitride film on high aspect ratio (HAR) features to create effective sidewall materials. This deposition is effective at temperatures as low as 320°C-350°C.

High Density, Low WER

Hydrazine Gas as a Nitride Source

Low Temperature, High Aspect Ratio

Hydrazine is an excellent low temperature thermal ALD nitride source as well as an excellent reducing agent. Next generation devices have low thermal budgets and high aspect ratio structures that create new challenges for conformal nitride films. Old solutions cannot meet these new challenges. Nitrogen from ammonia does not yield quality films below 400°C. Plasma delivery does not deliver the step coverage and conformality needed for high aspect ratio structures and causes surface damage.

Advantages of Hydrazine Gas

- Highly reactive, enabling thermal ALD at much less than 400°C

- No line of sight required, providing uniform films on high aspect ratio structures

- No oxygen or carbon, eliminating contamination

- Fewer device defects

- Better electrical performance

- Strong reducing agent for surface conditioning/cleaning of various metals

BRUTE Hydrazine Gas More Reactive than Ammonia

High Uniformity Low Temperature SiN

Silicon nitride materials are used in many memory and logic device elements including dielectric insulating layers, device layers, liners, spacers, etch hardmasks and etch stops. These various elements must all have high uniformity/conformality on 3D structures, low wet etch rate, and excellent dielectric properties. Emerging device requirements include low temperature deposition, which is not attainable with thermal ammonia processes.

No Substrate Damage

Unlike traditional plasma approaches, hydrazine gas does not damage the substrate surface. Plasma requires a line of site, leading to uniformity problems in HAR structures used in memory applications. Nitrogen created by plasma methods cannot deliver the step coverage and conformality needed for high aspect ratio structures. Hydrazine gas enables low resistivity, supporting better electrical characteristics in subsequent layers.

Low Oxygen

Plasma methods have a tendency to incorporate oxygen into the film. Low temperature ammonia plasma methods lead to incomplete dissociation, leaving residual hydrogen N-H bonds. This leads to very low growth per cycle and poor electrical properties. Raising plasma power can cause physical damage to HAR structures and other very thin films. In contrast, BRUTE Hydrazine has purity levels of less than 0.5ppm of moisture in the gas phase.

Higher Growth Rate

Researchers have found higher growth rates, higher density films and improved resistivity for films grown with hydrazine versus ammonia under similar low temperature conditions (Kummel). University of Texas (Dallas) researchers have reported similar effective results for hydrazine in low temperature deposition of silicon nitride.

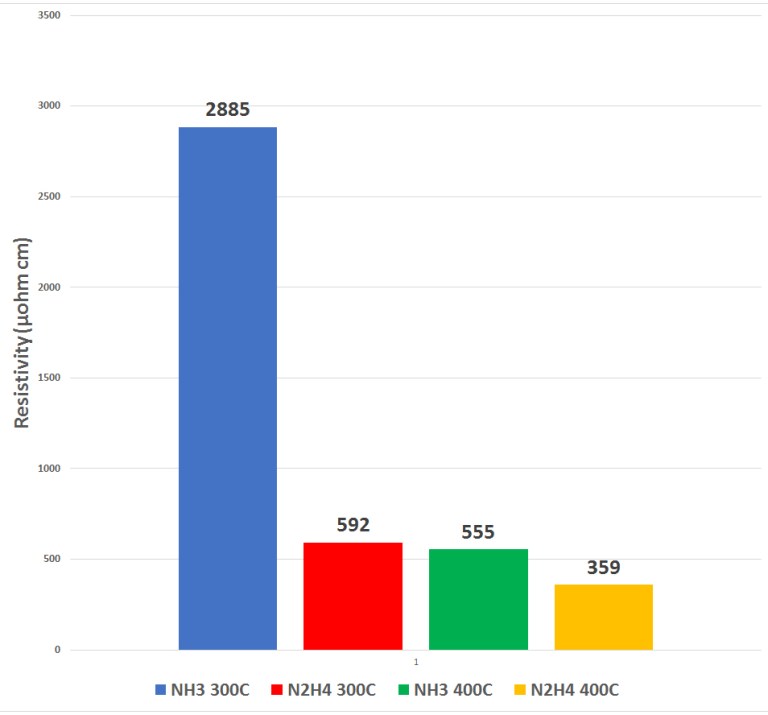

Low Resistivity

Thermal ALD of TiN below 400°C with NH3/TiCl4 is problematic as Chlorine content increases and resistivity properties escalate. Use of RASIRC BRUTE® Hydrazine has been shown to yield resistivity far lower that ammonia at 400°C and nearly 5x lower at 300°C (Kummel).

Low Temperature Thermal Deposition

Recent studies have shown that RASIRC BRUTE Hydrazine can be used to deposit high quality, thermal SiN films below 400°C. High SiN conformality and Refractive Index of (>1.9) at 350°C without the use of plasma shows strong potential for back-end applications such as sidewall spacers and passivation layers.